Automation systems for two 350 MW units based on the DCS ALSPA system, start-ups with optimization of the units' operation, acceptance tests and commissioning.

Automation systems for two 350 MW units based on the DCS ALSPA system, start-ups with optimization of the units' operation, acceptance tests and commissioning.

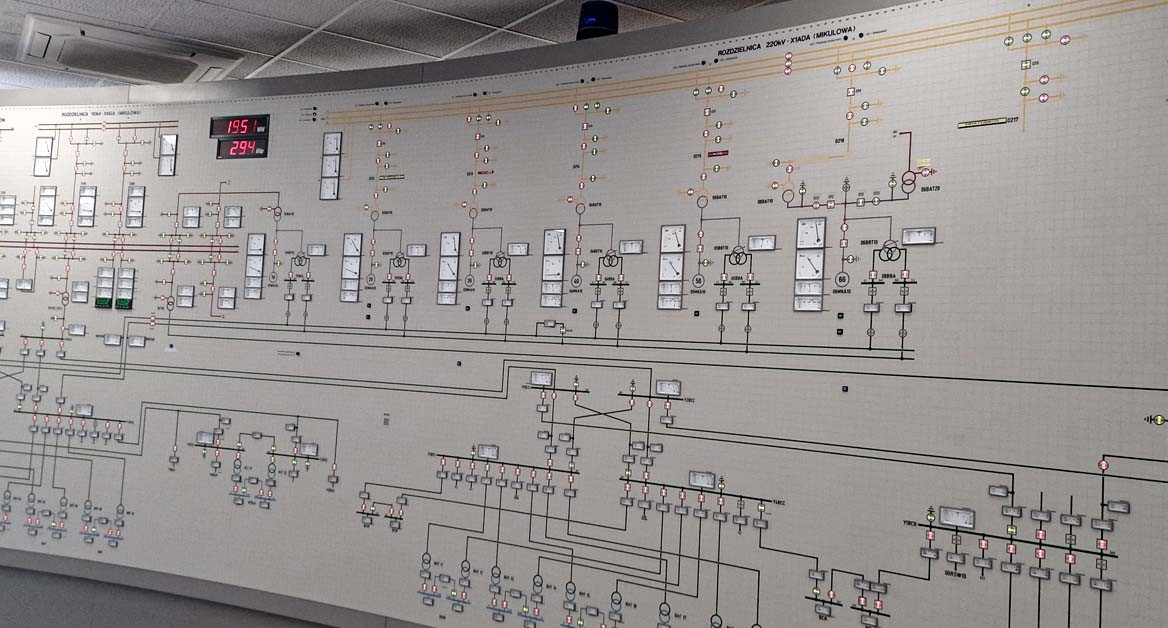

Complete modernization of units 1-3 in the electrical and measurement systemsindustries. Modernization of the power output system, 6kV and 0.4 kV switchboards, replacement of the DCS system with SPPA - T3000 from Siemens, master control system with LFC.

Turnkey construction of two heavy oil (mazut oil) preparation facilities at PGE Elektrownia Dolna Odra and PGE Elektrownia Opole power plants. Comprehensive implementation of the construction, technology, electrical industries and measurement systems.

Construction of a steam turbine control system along with a heat exhaust system based on the Siemens SPPA-T3000 system.

Comprehensive automation of an industrial boiler plant comprising 5 OPG230 boilers and one OPG 430 boiler, along with the implementation of a master control and stabilization system for the steam collector. The project was implemented on a Siemens PCS7 system.

Development and implementation of the comprehensive waste heat boiler control system based on Schneider systems.

Wykonanie systemów automatyki dwóch bloków 350 MW w oparciu o system DCS ALSPA, przeprowadzenie uruchomień wraz z optymalizacją pracy bloków, przeprowadzenie prób odbiorowych wraz z oddaniem do ruchu.

Marka ControlTec

Marka ControlTec Kariera

Kariera Zgłoszenie serwisowe

Zgłoszenie serwisowe Kontakt

Kontakt